A dye production enterprise specializes in the manufacturing of dyes, where the production process of dye intermediates demands high-performance fluid conveying equipment. Faced with corrosive media, high-temperature conditions, and stability requirements, the client sought a reliable pump solution to meet their production needs.

Challenges:In the dye intermediate production process, the medium exhibits high corrosiveness, making traditional pump equipment unsuitable for this specialized application. The client urgently needed a pump solution capable of withstanding corrosive media and exhibiting high-temperature performance to ensure the smooth operation of their production line.

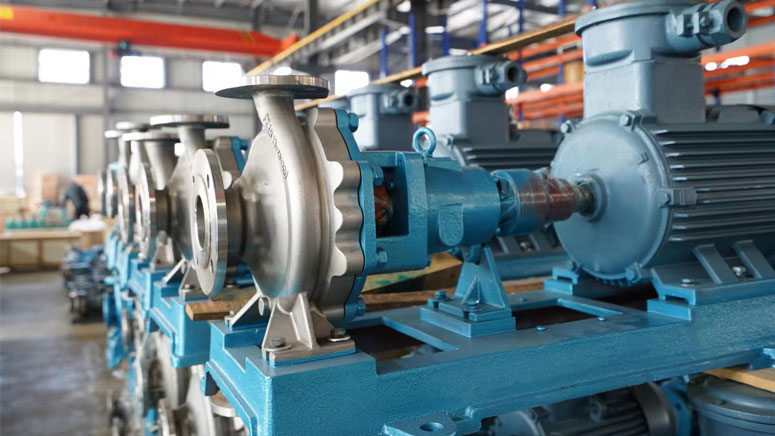

Solution:To meet the client's requirements, we recommended the IH series stainless steel centrifugal pump, renowned for its outstanding performance in highly corrosive and high-temperature environments. Key components of the pump are constructed from stainless steel, providing excellent corrosion resistance and accommodating the high-temperature requirements of the process.

Key Features and Advantages:

Stainless Steel Construction:Critical components are made of stainless steel, offering excellent corrosion resistance suitable for handling highly corrosive media.

High-Efficiency Temperature Resistance:The IH stainless steel centrifugal pump is designed for high-temperature conditions, ensuring reliable fluid conveyance even in extreme temperatures.

Stability:The centrifugal pump's stable structure and smooth operation reduce equipment maintenance frequency, enhancing overall production efficiency.

Comprehensive Performance:The IH series centrifugal pump not only suits corrosive media but also handles dye intermediates of different concentrations and temperatures, showcasing strong versatility.

Outcomes and Benefits:After implementing the IH stainless steel centrifugal pump, the client achieved significant results in the dye intermediate production process:

Improved Production Efficiency:Stable pump operation ensured the efficient conveyance of dye intermediates, enhancing overall production line efficiency.

Reduced Maintenance Costs:The use of stainless steel materials reduced equipment wear caused by corrosion, resulting in lower maintenance costs.

Environmentally Sustainable:The stainless steel construction aligns with environmental standards, reducing adverse impacts on the environment.

The IH stainless steel centrifugal pump has proven to be highly successful in the dye production enterprise's dye intermediate production process. This success case provides a feasible, high-performance fluid conveying solution for similar industrial sectors, meeting the demands of highly corrosive media while ensuring production stability and reliability.

+86 18130251359

+86 18130251359 teflowpumps@tlpumps.com

teflowpumps@tlpumps.com

+86+0563-5093318

+86+0563-5093318