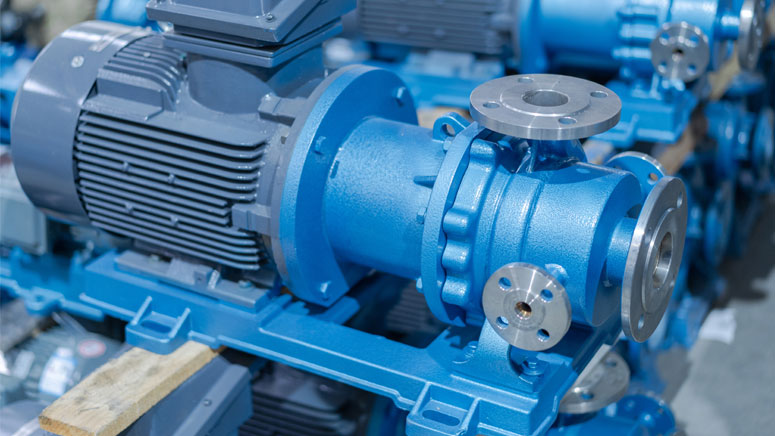

Stainless steel magnetic pumps, as common conveying devices, require careful consideration of various factors when deciding whether to insulate the pump body with a jacket. The decision to use jacket insulation depends on practical application scenarios. The following are situations in which considering jacket insulation for stainless steel magnetic pump bodies may be beneficial:

1. Temperature Variations in the Conveyed Media:

If the temperature of the conveyed liquid is subject to significant changes due to external environmental influences, insulating the stainless steel magnetic pump body with a jacket is advantageous. This helps maintain a stable conveying temperature, improving the efficiency of the pump.

2. Operation in High-Temperature Environments:

In environments with elevated temperatures, jacket insulation can assist in reducing the surface temperature of the pump body, alleviating the heat load during equipment operation, and minimizing heat dissipation, thereby enhancing the overall performance and lifespan of the pump.

3. Prevention of Crystallization or Solidification of the Medium:

For liquids prone to crystallization or solidification, jacket insulation effectively prevents the medium from crystallizing or solidifying within the pump body, preventing equipment blockages and damage.

4. Applications in Cold Regions:

In cold climates, to prevent the freezing of the liquid conveying medium within the pipes and pump body, jacket insulation is an effective measure. This helps maintain the normal operation of the pump and prevents damage caused by freezing.

5. Energy-Saving and Environmental Considerations:

Jacket insulation can also be regarded as an energy-saving and environmentally friendly measure. By reducing heat dissipation and lowering energy consumption, it improves energy efficiency, aligning with the principles of sustainable development.

When deciding whether to install jacket insulation on the pump body of a stainless steel magnetic pump, it is advisable to consider specific process requirements, medium characteristics, and environmental conditions. Regularly monitor pump body temperature, medium temperature, and ambient temperature, adjusting as needed to ensure the pump operates in optimal conditions. Ultimately, consulting with professional engineers or pump manufacturers for personalized advice tailored to specific applications is crucial to ensuring the rational use of jacket insulation.

+86 18130251359

+86 18130251359 teflowpumps@tlpumps.com

teflowpumps@tlpumps.com

+86+0563-5093318

+86+0563-5093318