Hydrogen peroxide, as a crucial chemical, demands meticulous handling during its conveyance. This article delves into the pivotal considerations for transporting hydrogen peroxide and provides recommendations for selecting the most suitable pump to ensure a safe and efficient conveyance process.

1. Characteristics of Hydrogen Peroxide:Hydrogen peroxide, being a strong oxidizing agent, requires consideration of its corrosiveness to materials during transportation. Additionally, its high reactivity necessitates maintaining stability throughout the conveyance process.

2. Conveyance System Design:In designing a hydrogen peroxide conveyance system, careful consideration must be given to the selection of materials for pipes, valves, and pumps. The recommended materials include corrosion-resistant options such as stainless steel or specialized plastics compatible with hydrogen peroxide.

3. Pump Selection:Choosing the right pump for hydrogen peroxide conveyance is paramount. Here are some recommendations:

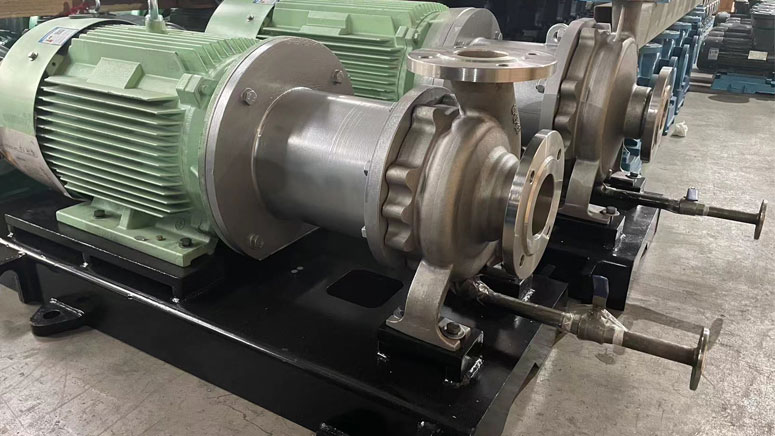

Centrifugal Pump:Suitable for moderate flow rates, providing relatively stable flow and pressure. Opt for materials resistant to corrosion.

Magnetic Drive Pump:Effectively transports hydrogen peroxide from one area to another, featuring excellent sealing performance and corrosion resistance.

Self-Priming Pump:Ideal for extracting hydrogen peroxide from deep wells or sources, ensuring reliable conveyance.

4. Regular Maintenance:Regardless of the pump chosen, regular maintenance is crucial for ensuring the system's reliability. Cleaning, inspection, and replacement of worn components extend the pump's lifespan, reducing the risk of malfunctions.

5. Safety Measures:In a hydrogen peroxide conveyance system, it is advisable to establish comprehensive safety measures, including leak detection, emergency shutdown devices, and personnel training. Ensuring that operators are familiar with proper responses to potential risks is essential.

Transporting hydrogen peroxide requires systematic planning and strict adherence to operational procedures. The selection of an appropriate pump is a key factor in ensuring the safety and efficiency of the conveyance system. By following proper considerations and safety measures in both design and operation, a solid foundation is established to guarantee the reliability and stability of the hydrogen peroxide conveyance system.

+86 18130251359

+86 18130251359 teflowpumps@tlpumps.com

teflowpumps@tlpumps.com

+86+0563-5093318

+86+0563-5093318