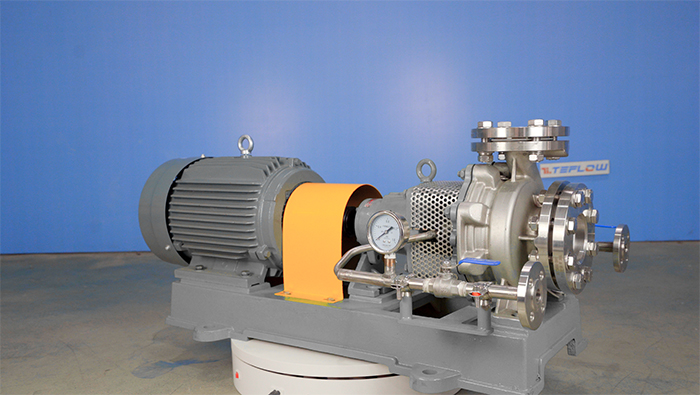

Recently, Tenglong Pump and Valve successfully completed production and commissioning of the IH stainless steel centrifugal pump (matched with the Plan54 mechanical seal flushing solution) customized for a large chemical company and was officially delivered to the customer. This batch of equipment will be used for silicate medium transportation in the core production line of the enterprise, marking that Tenglong Pump & Valve's high-end customized service capabilities in the chemical industry have reached a new level.

The company's production line medium is highly corrosive, prone to crystallization, high temperature and high pressure, etc., which places strict requirements on the corrosion resistance, sealing stability and crystallization resistance of the conveying equipment. The customer's original equipment has high maintenance costs due to frequent leakage, sealing failure and other problems, and urgently needs a set of efficient and reliable pump and valve solutions.

The Tenglong Pump and Valve Technology Team conducted in-depth on-site customer research and, based on the characteristics of the media, ultimately determined a customized design with an IH stainless steel centrifugal pump as the core and an API Plan54 mechanical seal flushing solution to fully overcome the industry's problems of media leakage and short seal life.

Plan54 mechanical seal flushing solution is an external flushing system that continuously injects buffer solution through an independent cleaning liquid circulation loop to isolate the medium from the sealing surface, thereby preventing corrosive or particulate matter from damaging the sealing surface, effectively extending the service life of the mechanical seal. This solution is particularly suitable for handling high temperature, high pressure, highly corrosive and easily crystallized media. It can not only ensure the efficient operation of the pump, but also significantly reduce maintenance costs.

During the design, manufacturing and testing process of the project, Tenglong pumps and valves always adhere to high standards and strict requirements, and strive to achieve perfection from material selection to processing technology, from strict quality control to all-round simulated working environment testing. Through these high-standard operations and controls, Tenglong Pumps and Valves ensures that every pump produced can withstand the test of harsh working environments.

Before the official delivery of the project, Tenglong Pump and Valve's technical engineers also provided installation and commissioning guidance and employee training for the customer to ensure that the operators were proficient in the operation and maintenance of the equipment and maximized the effectiveness of the equipment.

In the future, Tenglong Pumps and Valves will continue to improve its technology research and development and innovation capabilities based on a deep understanding of customer needs and industry trends, and continuously launch more efficient, environmentally friendly and intelligent pump and valve products and solutions to provide more industry customers with excellent services and support.

+86 18130251359

+86 18130251359 teflowpumps@tlpumps.com

teflowpumps@tlpumps.com

+86+0563-5093318

+86+0563-5093318