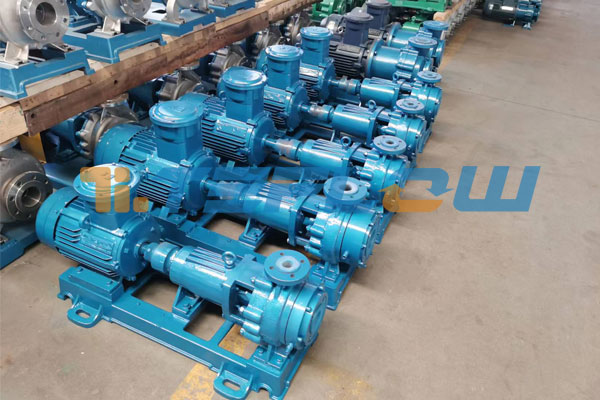

In industrial settings, the safe and efficient handling of corrosive liquids is of utmost importance. One vital equipment that plays a crucial role in this process is the centrifugal acid pump. Designed specifically to handle corrosive fluids, this pump offers a versatile solution for various industrial applications. In this article, we will explore the features, benefits, and applications of the centrifugal acid pump.

Superior Corrosion Resistance: One of the primary advantages of the centrifugal acid pump is its exceptional corrosion resistance. These pumps are constructed with materials specifically chosen to withstand the corrosive properties of acids and other aggressive chemicals. Typically, they are made from high-quality corrosion-resistant materials such as stainless steel, alloy, or polypropylene. This ensures the longevity and reliability of the pump, even when exposed to highly corrosive environments.

Efficient Fluid Handling: Centrifugal acid pumps operate based on the principles of centrifugal force, allowing for efficient fluid handling. The pump impeller rotates rapidly, creating a centrifugal force that propels the fluid outwards. This mechanism enables the pump to move large volumes of corrosive liquids with ease, making it suitable for various industrial processes such as chemical transfer, wastewater treatment, and metal surface treatment.

1.Versatility in Application: Centrifugal acid pumps find application in a wide range of industries and processes. Some common areas where these pumps are extensively used include:

2.Petrochemical industry: Centrifugal acid pumps are crucial for handling corrosive substances in oil refineries, chemical plants, and petrochemical processing facilities.

3.Pharmaceutical industry: These pumps are utilized for transferring acids and corrosive solvents in the production of pharmaceuticals and laboratory processes.

4.Metal finishing: Centrifugal acid pumps play a vital role in metal surface treatment processes, including pickling, electroplating, and anodizing.

5.Energy Efficiency: Centrifugal acid pumps are known for their energy efficiency. The design of these pumps minimizes energy consumption while maximizing fluid transfer capabilities. With the use of high-efficiency motors and optimized impeller designs, these pumps can significantly reduce energy costs in industrial operations.

6.Easy Maintenance and Operation: The centrifugal acid pump is engineered for easy maintenance and operation. They are designed with simple construction, allowing for quick disassembly and access to key components. Routine maintenance tasks such as impeller inspection, seal replacement, and motor maintenance can be performed efficiently, minimizing downtime and ensuring the pump operates at its optimal performance.

The centrifugal acid pump is a versatile and reliable solution for handling corrosive fluids in various industrial applications. With its superior corrosion resistance, efficient fluid handling capabilities, and energy efficiency, this pump proves to be an invaluable asset in industries such as petrochemicals, pharmaceuticals, and metal surface treatment. Its easy maintenance and operation further enhance its appeal. When it comes to safely and effectively managing corrosive liquids, the centrifugal acid pump stands as a trusted and essential piece of equipment in the industrial landscape.

+86 18130251359

+86 18130251359 teflowpumps@tlpumps.com

teflowpumps@tlpumps.com

+86+0563-5093318

+86+0563-5093318