The PLAN23 scheme, also known as the hanging pot scheme, is a cooling solution designed for high-temperature applications where mechanical seals are prone to running dry. This scheme utilizes a hanging pot along with a mechanical seal equipped with a pumping ring, enabling the mechanical seal to circulate autonomously. The circulating liquid is directed through a cooling device and returned to the seal chamber, establishing an effective cooling cycle. This solution is particularly suitable for high-temperature water (≥75°C) and conditions where mechanical seals may experience dry running, such as in self-priming pumps.

Detailed Explanation:

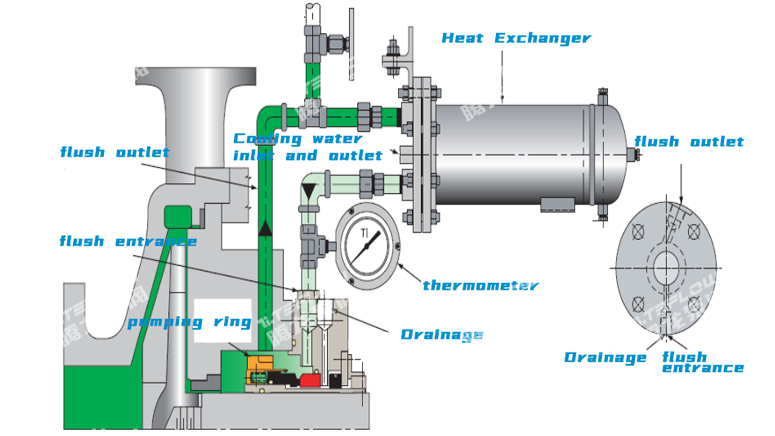

1.Hanging Pot and Mechanical Seal with Pumping Ring:The design of the hanging pot and the mechanical seal with a pumping ring in the PLAN23 scheme allows the mechanical seal to circulate independently, enhancing the cooling effect.

2.Liquid Circulation within the Seal Chamber:The pumping ring is responsible for drawing liquid out of the seal chamber, passing it through the cooling device, and then returning it to the seal chamber, creating a continuous circulation process.

3.Cooling Device:The cooling device is responsible for lowering the temperature of the liquid in circulation. The hanging pot scheme maximizes the cooling effect, ensuring the stable operation of the mechanical seal under high-temperature conditions.

4.Reasons for Adoption:The adoption of the PLAN23 scheme is justified by its ability to cool a small amount of liquid efficiently. This approach, under low load conditions, enhances the cooling of the mechanical seal, broadening the range of fluid vaporization and improving water lubrication.

Application Areas:The PLAN23 scheme is applicable in the following scenarios:

1.Conditions Where Mechanical Seals are Prone to Dry Running:For example, in self-priming pumps like FZB self-priming pumps and unloading centrifugal pumps. In such cases, the PLAN23 scheme effectively improves the cooling of the mechanical seal, extending its lifespan.

2.Leakage of Media Without Particulate Matter:For conditions where the medium has no particulate matter, and the leakage of the medium is allowed within the mechanical seal's permissible range. An example includes alkaline solutions (sodium hydroxide, potassium hydroxide), where the medium is crystal-free and in contact with air.

High-Temperature Conditions

For high-temperature conditions, such as hot water (>75°C), where the hanging pot scheme effectively protects the formation of a liquid film on the rubbing surfaces of the mechanical seal, improving its stability.

The PLAN23 scheme, with its hanging pot design, provides an efficient and reliable cooling solution for mechanical seals in high-temperature applications. In specific conditions, its design effectively enhances sealing performance, prolonging the seal's operational life, making it an ideal choice for handling high-temperature and dry running mechanical seal scenarios.

+86 18130251359

+86 18130251359 teflowpumps@tlpumps.com

teflowpumps@tlpumps.com

+86+0563-5093318

+86+0563-5093318