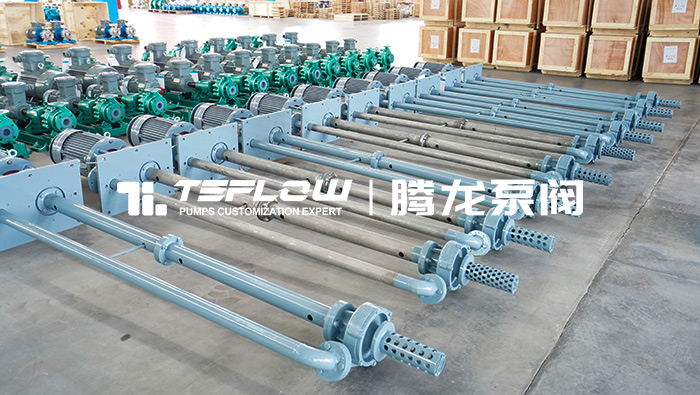

Recently, in the shipping workshop of Tenglong Pump Industry, a batch of submersible pumps (concentrated sulfuric acid unloading pumps) that have undergone rigorous testing are ready to be shipped to the customer's production site. These pumps will handle the core tasks of unloading and transporting highly concentrated sulfuric acid, ensuring safe production for customers with their superior performance.

Concentrated sulfuric acid, a high-risk transportation checkpoint in chemical production, is highly corrosive and requires extremely stringent requirements for pump materials, structural design, sealing performance, and operational stability due to its high-temperature properties. Any minor leak or equipment failure could lead to serious safety hazards and production interruptions.

After receiving the customer's request, the Tenglong Pump Industry technical team conducted an in-depth on-site investigation of the operating conditions. They tailored a solution specifically for the customer, taking into account the highly corrosive nature of concentrated sulfuric acid, operating temperature, concentration, and flow and head parameters. The core flow components of these submersible pumps are constructed of high-quality fluoroplastics and high-grade stainless steel, ensuring excellent corrosion resistance. Furthermore, the optimized hydraulic model and structural design ensure stable operation within the high-efficiency range, effectively preventing cavitation and vibration and extending the equipment's service life.

Before leaving the factory, this batch of submersible pumps completed a number of strict quality inspection procedures including static pressure testing, dynamic operation testing, sealing performance testing and nitrogen pressure maintenance testing. All data met or even exceeded the design standards, ensuring that the equipment could be put into operation quickly and operate stably after arriving at the site with a "zero hidden danger" state.

Delivering products to customers on time is a commitment Tamron upholds. We are fully aware of the importance of this batch of equipment to the customer's production line. The entire team worked closely together to overcome the challenges of the production cycle and ultimately ensured the on-time shipment of the equipment.

In the future, Tenglong Pump Industry will continue to be guided by market demand and driven by technological innovation, and will continue to provide customers with safer, more efficient and more durable industrial pump and valve products and comprehensive service support, helping customers improve their core competitiveness and achieve win-win development.

+86 18130251359

+86 18130251359 teflowpumps@tlpumps.com

teflowpumps@tlpumps.com

+86+0563-5093318

+86+0563-5093318